Avdel® NeoBolt® XT Lockbolts

High strength, vibration resistant, and eco-friendly, the NeoBolt® XT lockbolt fastening system is designed for use in heavy-duty structural applications. No pin break ensures anti-corrosion finish remains intact for the lifetime of the installation. This lockbolt provides a collar "fit-up" feature for easy pre-assembly.

Assembly applications where NeoBolt® fasteners are found include railway, truck & trailer, commercial vehicles, solar & wind energy, bridge building, mining equipment, screening equipment, fencing and security screens, construction, overland infrastructure, and power and utility services.

Available in many diameters and lengths, NeoBolt® XT lockbolts can be placed with a range of installation tools featuring fastener-specific nose assemblies.

Fast Facts:

- No pin break

- No metal waste; eco-friendly

- Avoids corrosion at stem break point (vs. traditional lockbolts)

- Reduced pin size and weight for lower warehousing and shipping cost

- Locking groves for superior vibration resistance (vs. traditional lockbolts)

- Collar “fitup” feature allows rapid pre-assembly of joint

- Fine pitch pin groove design for superior vibration resistance vs. traditional lockbolts and nut & bolt settings

- No need to support the pin during the placing operation

- Ideal for upside-down installation

- Radial bar indicators on flange for quick visual swage inspection upon placing

- Fast, non-operator reliant installation for improved productivity

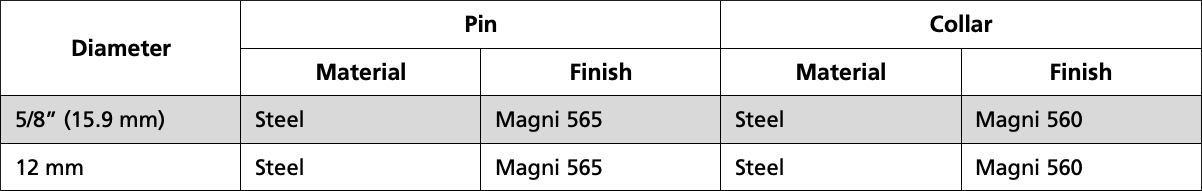

| NEOBOLT® XT SPECIFICATIONS |

|---|