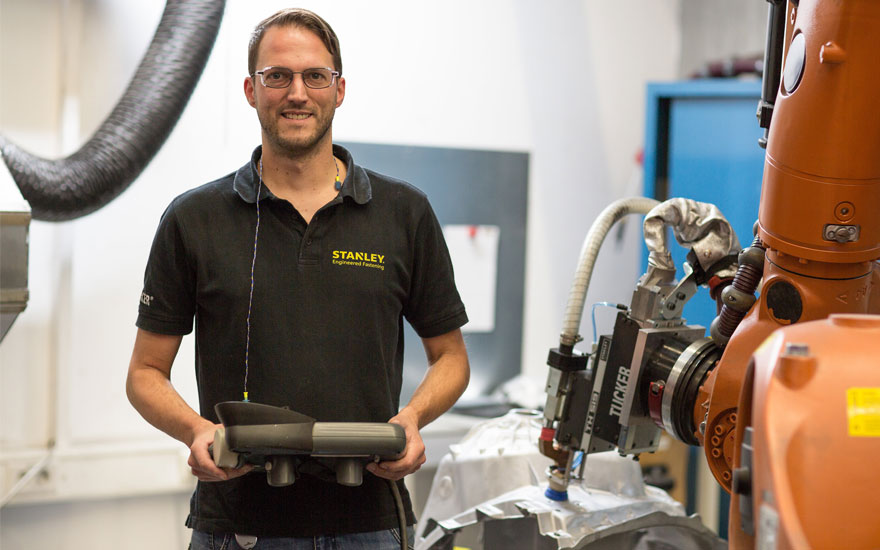

A Tucker® Innovation Story

Typical door panel fixations contain a long list of problems regarding water-tightness, corrosion issues, design change inflexibility, and a short clip life-span. A major premium automotive OEM converted all the doors of its car fleet to a unique Tucker® no-hole solution, only available from STANLEY® Engineered Fastening, including:

- A customized weld stud

- A highly engineered plastic clip

- Weld system with single-sided access and highest quality weld results

- Tucker® service on-site, equipment training, and genuine Tucker® spare parts for highest availability

This complete door panel fastening solution now allows for easy assembly and disassembly, all from one provider.

Tucker® Self-Piercing Rivet

Featuring higher dynamic stability than resistance spot welding and fully automated feed riveting without pre-punching, STANLEY® Engineered Fastening will develop the right type SPR system for you.

Learn More

Studs & Equipment

Tucker® welding equipment sets our weld studs which are the link between the base material and the components to be fastened. Useful in all possible fastening tasks.

Need Help Finding the Right Solution?

Let our experts provide recommendations for your project or application.